Homeowners are increasingly leaning to crushed asphalt driveways for their cheap, eco-friendly, and durable nature. Composed of 100 percent recycled asphalt millings (the byproduct of roadwork repairs and construction), the material gives a second life to what would otherwise be littering landfills.

![Construction workers installing a crushed asphalt driveway using heavy machinery and hand tools, with the title "Crushed Asphalt Driveway: Pros & Cons, Ultimate Guide [2025]" and the Asphalt Calc Pro logo in the corner.](https://asphaltcalcpro.com/wp-content/uploads/2025/04/Crushed-Asphalt-Driveway-Pros-Cons-Ultimate-Guide-2025-1024x536.webp)

In 2025, demand for eco-friendly paving solutions is on the rise, and crushed asphalt is one of the great alternatives to traditional concrete or gravel that to the next level. But is it suitable for your residence?

In this guide, we’ll dive deep into:

- 2025 Cost Breakdowns (materials, labor, regional variations)

- Pros & Cons compared to gravel, concrete, and pavers

- Step-by-Step Installation (DIY vs. professional)

- Long-Term Maintenance Tips (sealing, repairs, seasonal care)

- Local Contractor Tips (how to vet providers, red flags to avoid)

- FAQs (lifespan, weather resistance, and more)

Let’s get started.

What is a Crushed Asphalt Driveway?

Crushed asphalt, also known as recycled asphalt pavement (RAP), consists of ground-up asphalt chunks from old roads, parking lots, or driveways. When compacted, it binds to itself and creates a stable, semi-permeable surface that’s perfect for driveways.

Why Choose Crushed Asphalt?

- Eco-Friendly: Recycling asphalt minimizes the need for mining of new materials and disposal of landfill waste.

- Cost Savings: Much more economical, up to 60–70% fewer costs than new asphalt.

- Durability: Resistant to heavy vehicles and severe weather.

Did You Know? The U.S. recycles over 99% of asphalt pavement annually, saving taxpayers billions.

2025 Crushed Asphalt Driveway Cost Breakdown

As of 2025, crushed asphalt driveways are an affordable and eco-friendly alternative to traditional paving, with installation costs typically ranging from $2.00 to $6.50 per square foot. Tough, low-maintenance, and made from 100% recycled materials, they’re ideal for homeowners looking to balance cost, durability, and sustainability. In the sections below, we’ll break down per-square-foot pricing, regional variations, and the key factors that can influence your total project cost.

Cost Per Square Foot

| Component | Low-End | High-End |

|---|---|---|

| Materials (Crushed Asphalt) | $0.50 | $2.00 |

| Labor | $1.00 | $3.00 |

| Compaction & Grading | $0.50 | $1.50 |

| Total | $2.00 | $6.50 |

Example: A 1,000 sq ft driveway costs 2,000 – 6,500 installed.

Factors Affecting Cost

Regional Pricing:

- Texas: 2.50–5.00/sq ft (abundant recycled materials).

- Northeast: 4.00–7.00/sq ft (higher labor costs).

Driveway Thickness: 3–4 inches is standard. Adding a base layer of gravel increases costs by 1.00–2.00/sq ft.

Delivery Fees: 100–300 for rural areas.

Now you can estimate your project using our free Asphalt Cost Calculator

Crushed asphalt is less expensive than concrete or new asphalt, but proper compaction and grading is critical to avoid sinking and cracking. Then bid your project out to local contractors to check rates – especially if your project will need additional excavation or a thicker base.

Pro Tip: Check for local recycled asphalt

Crushed Asphalt vs. Gravel, Concrete, and Pavers

The best driveway material for you will depend on your budget, local climate, and long-term maintenance tolerance. Below we compare the cost, lifespan, maintenance and eco-friendliness of crushed asphalt, gravel, concrete and pavers to guide your decision.

| Material | Cost/sq ft | Lifespan | Maintenance | Eco-Friendliness |

|---|---|---|---|---|

| Crushed Asphalt | 2–2–6.50 | 15–20 yrs | Low | ★★★★★ |

| Gravel | 1.50–1.50–4 | 10–15 yrs | High | ★★★☆☆ |

| Concrete | 6–6–15 | 30+ yrs | Medium | ★★☆☆☆ |

| Pavers | 10–10–30 | 25+ yrs | High | ★★★☆☆ |

- Gravel: Upfront is less expensive than dirt, but you need to regrade it often.

- Concrete: Long lifespan but 3x more expensive.

- Pavers: Aesthetic appeal but high installation costs.

Why Use Crushed Asphalt?

✅ Affordable for the homeowner (half the price of concrete).

✅ Trashy — Eco-warriors (recycling, saving trash from landfills).

✅ Rapid projects (applicable in days, contrary to cure-heavy concrete).

The Final Verdict: Crushed Asphalt is the winner if cost, sustainability and durability are top priorities for you. Choose gravel only if you don’t mind maintenance

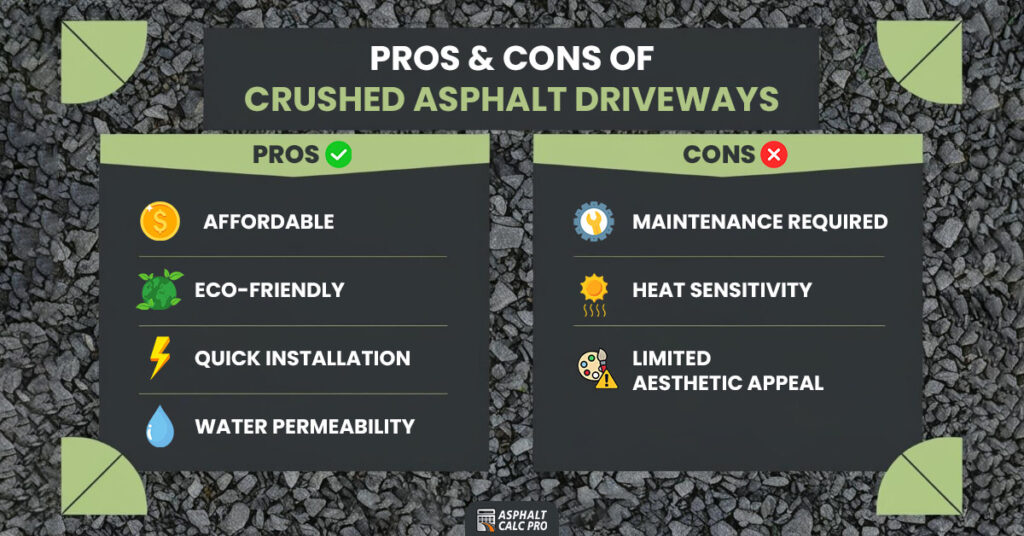

Pros & Cons of Crushed Asphalt Driveways

Crushed asphalt driveway is a wise option for many homeowners, though it’s not an optimal one for every scenario. Below, we dissect the pros and cons as well as debunk a common myth, so you can determine whether it’s right for your property.

Pros

- Affordable: Up to 60% less expensive than new asphalt or concrete. At 2–6.50/sq ft, it’s the cheapest paved surface available.

- Eco-Friendly: 100% recycled asphalt, minimizes landfill usage. The EPA recommends it as an eco-friendly paving solution with a low carbon footprint.

- Quick Installation: Use your base within 1–2 days of compaction-no cure time (e.g., concrete takes weeks).

- Water Permeability: Water can drain through, which helps limit runoff and flood risk – great for places that see heavy rain.

Cons

- Maintenance Required: Need to be sealed every 3–5 years to keep surface from degrading (but still less maintenance than gravel).

- Heat Sensitivity: May soften somewhat in extreme heat (like the Southern states), but will not melt like new asphalt.

- Limited Aesthetic Appeal: Lacks the polished look of concrete or pavers—best for functionality over curb appeal.

Recycling asphalt minimizes landfill waste, according to the EPA’s sustainability guidelines.

Myth Buster: “Crushed asphalt is the same as gravel.”

False! Unlike loose gravel, crushed asphalt binds together when compacted, creating a smoother, more stable surface that resists shifting and ruts.

Step-by-Step Installation Guide

If you have the time and inclination, a crushed asphalt driveway can be a rewarding and DIY friendly project, but if not, there are professionals who can help get the job done. We break down the entire process, below, step by step, and share when it makes sense to call in experts.

DIY Installation (For Handy Homeowners)

- Site Preparation

- Clear debris and mark boundaries with stakes.

- Excavate 6–8 inches of soil for the base and asphalt layers.

- Base Layer

- Add 4 inches of crushed stone (for drainage).

- Compact with a plate compactor ($150/day rental).

- Asphalt Application

- Spread 3–4 inches of crushed asphalt.

- Mist lightly with water to reduce dust.

- Compaction

- Use a roller or plate compactor to bind the millings.

- Keep repeating the process until the surface is firm and flat.

Time Required: 2–3 days for 1,000 sq ft driveway.

When to Hire a Pro

- Sloped Driveways: Improper grading can lead to erosion.

- Large Projects: Professionals handle bulk material delivery and machinery.

Cost of Professional Installation: 3–8/sq ft (includes labor, materials, and equipment).

While DIY is cheap, there are times when you need an expert. Driveways that are steeply sloped need to be precisely graded so as not to erode or collect water – a job that professionals are able to perform with laser-guided equipment. Big projects (1,500-plus square feet) also tend to be well-suited to pro installation, since contractors can best coordinate

The average cost for professional installation is between $3.00 and $8.00 per square foot, including labor, materials, and equipment. You may also want to get multiple quotes to make sure you’re not overpaying, and check if they discount for using recycled asphalt.

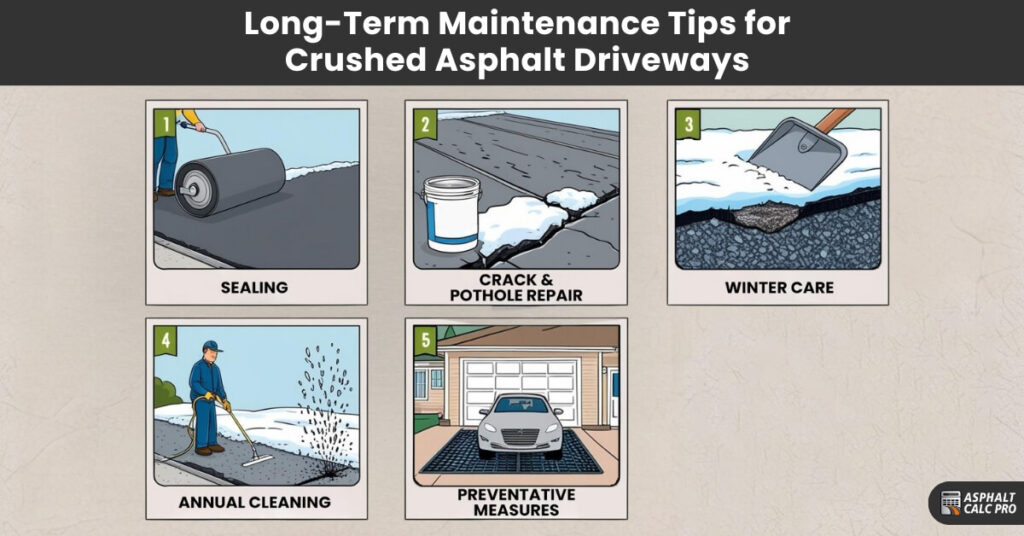

Long-Term Maintenance Tips for Crushed Asphalt Driveways

A well-maintained crushed asphalt driveway can last 15–20 years – but only with proper care. Follow these essential maintenance steps to protect your investment and keep your driveway looking its best.

Sealing (Every 3–5 Years)

Sealing is the most important maintenance task for crushed asphalt driveway. A high-quality sealant:

- Protects against UV rays (which can dry out and fade the surface)

- Prevents water penetration (reducing cracks and potholes)

- Restores the deep black color for a fresh, uniform look

Product Recommendation:

Asphalt Sealcoat Pro – This premium sealant lasts 30% longer than standard options and provides superior protection against weathering.

Please note: “Asphalt Sealcoat Pro” is a product recommendation based on general information. Availability and suitability may vary. We encourage you to research and compare other asphalt sealant options available in your local area.

Pro Tip: Pressure wash annually to remove oil stains and debris.

Crack & Pothole Repair

Address damage as soon as it appears to prevent further deterioration:

- Small cracks (less than ¼ inch): Fill with asphalt emulsion to seal and waterproof.

- Larger cracks/potholes: Remove loose material, then patch with fresh crushed asphalt and compact thoroughly.

Pro Tip: Keep a bag of crushed asphalt on hand for quick repairs—it blends seamlessly with your existing driveway.

Winter Care

Cold weather can be tough on asphalt. Protect your driveway with these tips:

- Shovel carefully: Use a plastic shovel (metal blades can scratch the surface).

- De-ice wisely: Opt for calcium chloride instead of rock salt, which erodes asphalt over time.

- Clear snow promptly: Prevents ice buildup that can lead to cracks.

Annual Cleaning

- Pressure wash once a year to remove oil stains, dirt, and debris.

- Spot-clean spills (especially oil) immediately with a degreaser to prevent permanent staining.

Preventative Measures

- Avoid sharp turns (which can displace loose millings).

- Use driveway mats under heavy vehicles or RVs to distribute weight evenly.

Final Thought: A little maintenance goes a long way! Spending 1–2 hours per year on upkeep can extend your driveway’s lifespan by 5+ years.

Finding Local Contractors

Searching for “crushed asphalt driveway near me”? Choosing the right contractor is just as important as selecting the material. Follow these steps to find a qualified professional who delivers quality work at a fair price.

How to Vet Contractors

Not all contractors are equal—here’s how to separate the best from the rest:

1. Check Reviews & Reputation

- Look for feedback on Google My Business, Yelp, and the Better Business Bureau (BBB).

- Red flags: Multiple unresolved complaints about missed deadlines, poor workmanship, or hidden fees.

- Green flags: Consistent praise for communication, professionalism, and durability.

2. Verify Credentials

- Licensing: Ensure they hold a valid state contractor’s license (requirements vary by location).

- Insurance: Confirm general liability and workers’ compensation coverage to protect yourself from accidents or damage.

3. Compare Estimates

- Get 3–5 detailed quotes to compare pricing fairly.

- A proper estimate should include:

- Materials (type/quality of crushed asphalt)

- Labor (grading, compaction, cleanup)

- Additional fees (delivery, permits, disposal)

Questions to Ask Suppliers:

- “Is the asphalt sourced from local recycling plants?”

- “Do you offer delivery and onsite compaction services?”

Environmental Impact & Sustainability

Choosing crushed asphalt driveway isn’t just a budget-friendly decision – it’s an eco-conscious one. Here’s how this recycled material benefits the planet while delivering a durable driveway.

Key Environmental Advantages

1. Significant Carbon Savings

- Recycling asphalt uses 60% less energy than producing new asphalt.

- Fact: Reprocessing 1 ton of asphalt saves 1.3 barrels of oil—equivalent to powering a car for over 1,000 miles.

2. LEED Certification Contributions

- Crushed asphalt qualifies for LEED (Leadership in Energy and Environmental Design) credits in sustainable construction.

- Ideal for eco-friendly home projects aiming for green building certifications.

3. Wildlife & Water Protection

- Permeability: Unlike solid concrete, crushed asphalt allows water to filter through, reducing:

- Runoff pollution (prevents chemicals from washing into rivers/lakes).

- Flood risks (absorbs rainwater like a sponge).

4. Waste Reduction

- 100% recycled: Diverts old asphalt from landfills—the U.S. recycles 80 million tons annually.

- Closed-loop system: When your driveway ages, it can be recycled again.

Conclusion

Crushed asphalt driveways offer unmatched value for budget-friendly, eco-conscious homeowners. To recap:

- Cost: 2–2–6.50/sq ft installed.

- Durability: 15–20 years with maintenance.

- Eco-Perks: 100% recycled and permeable.

Ready to Start?

- Calculate Costs: Use our Asphalt Tonnage Calculator.

- Find Contractors: Check our Local Asphalt Installers Guide.

- Ask Questions: Comment below or contact our team!

Frequently Asked Questions (FAQs)

Is crushed asphalt good for driveways?

Yes! Durable, eco-friendly, and costs 2–6.50/sq ft.

Does crushed asphalt make a good driveway?

Yes. Stable, low-maintenance, and lasts 15–20 years.

How much does a crushed asphalt driveway cost?

2.00–6.50/sq ft installed (1,000 sq ft = 2,000–6,500).

Is crushed asphalt better than gravel?

Yes for stability (binds when compacted); gravel is cheaper (1.50–4/sq ft).

How long does a crushed asphalt driveway last?

15–20 years (with sealing every 3–5 years).

What is crushed asphalt used for?

Driveways, roads, parking lots, and walkways (recycled from old pavement).